Safety comes first.

Safety isn’t just a priority—it’s our first core value. Every member of our Pack plays a role in creating a safe work environment. In every gallon we deliver and every mile we drive, safety comes first.

We are committed to safeguarding the health and well-being of our employees, their families, customers, and the communities we serve. Our commitment extends beyond compliance and regulations—we actively seek ways to enhance safety through continuous education, training, and awareness (we have an entire department dedicated to safety).

Safety—it’s who we are.

ZERO.

our goal is zero preventable incidents that impact our Wolf Pack or the public

Safety in Action: Inspections

Facility inspections

To ensure a safe and efficient work environment, all Wolf facilities undergo thorough quarterly safety inspections. These formal reviews are supplemented by regular walk-arounds to catch any issues early and uphold our high standards. Facility inspections are conducted by our Safety Department—providing oversight from experienced team members who know our operations inside and out.

Equipment & Truck Inspections

Our equipment and fleet are inspected with the same level of diligence and care. Operators perform daily inspections on their trucks and equipment to catch any concerns before the start of each shift. In addition to these daily checks, all units are serviced and inspected at routine mileage or time-based intervals by our in-house mechanics. These service intervals are carefully tracked through Samsara to ensure timely maintenance. All tank trailers and route truck tanks are certified according to current regulations. Drivers are trained to complete the required pre- and post-trip inspections outlined in CDL protocols, and we continue to reinforce this training as their careers progress.

Outside Inspections

Coast Guard

Insurance representatives & auditors

Engineer consultants

Safety in Action: Memos, Training, & Real-Life Practice

Safety Minute Memos

weekly

Every week, the Wolf Pack gets a powerful, one-page safety update covering one topic. These quick reads are required reading for every member of our Pack.

Highlights

- ✓ Slips & Fall Prevention

- ✓ Eye Fatigue

- ✓ Lithium Battery Hazards

- ✓ CPR Week

- ✓ Human Trafficking Awareness

Focus on Safety

monthly

Our monthly trainings go deeper—giving Pack members hands-on knowledge about the most important safety topics in our industry and our lives.

Highlights

- ✓ Hearing Protection

- ✓ Tackling Fatigue

- ✓ Safely Reversing

- ✓ Railroad Crossing Safety

- ✓ Bloodborne Pathogens

In-person Safety Training

ongoing

Our Safety Team leads Pack in-person training.

Highlights

- ✓ Facility & equipment hazards

- ✓ Product safety reminders

- ✓ MSHA certifications

Safety in Action: Ride Alongs

At Wolf, safety behind the wheel is a top priority. Our driver evaluations focus on the safe operation of vehicles and equipment, while also supporting our drivers with guidance to help them succeed in their roles. During these evaluations, we assess not only driving habits, but also review loading and unloading procedures to ensure that our standard operating procedures (SOPs) are consistently followed.

All CDL holders participate in periodic ride-alongs with a representative of our Safety Team. These sessions emphasize safe driving practices and provide valuable opportunities for coaching and feedback. Drivers with less than two years of CDL experience are evaluated quarterly, while more experienced drivers undergo semi-annual evaluations. This proactive approach ensures our team remains sharp, compliant, and committed to the highest safety standards.

Safety in Action: Samsara

Every vehicle in our fleet—from our sales team’s Chevrolet Equinox to our fully loaded 40-ton Mack Granite™ transport trucks and trailers—is equipped with Samsara technology. This includes AI-powered dash cameras, real-time alerts, GPS fleet tracking, and advanced safety insights. Samsara helps our Pack stay aware on the road and get home safely every day—no matter the conditions.

Samsara Improves our Pack’s Safety & Efficiency

Proactive, not reactive

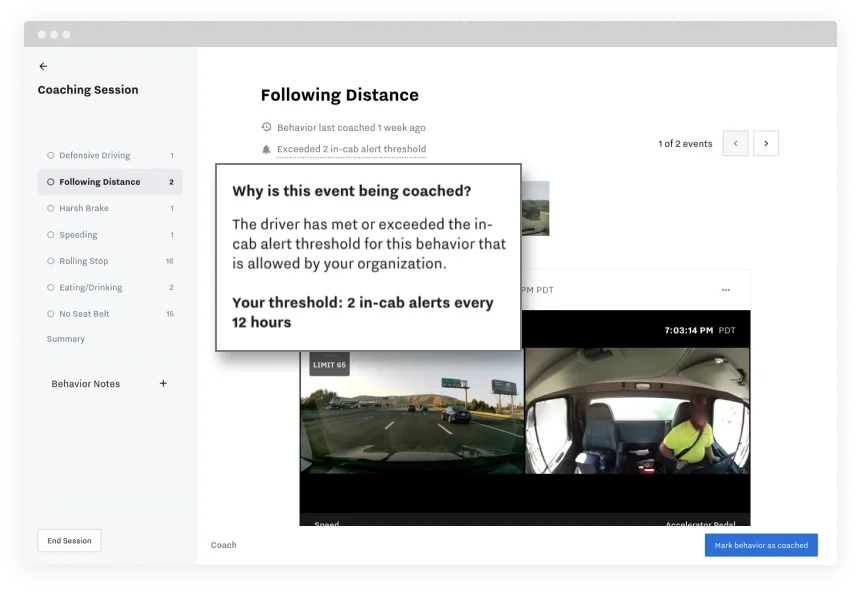

Samsara’s in-cab cameras and smart technology provide industry-leading safety insights that help us stay ahead of behaviors that can lead to accidents. Our drivers receive real-time alerts that help them avoid hazards, correct risky driving habits, and stay protected on the road. These proactive tools significantly increase the safety of our Pack, our fleet, our products, and the customers we serve.

Real time risk avoidance

With Samsara’s driver-first approach, we empower our drivers to take control of their own safety through critical in-cab coaching. Our team receive real-time feedback, allowing them to self-coach and correct their behaviors! By leveraging data-driven insights, Samsara gives us the ability to act proactively. This approach not only helps prevent safety events but also fosters continuous improvement, ensuring drivers receive the right coaching at the right time to keep our roads safer.

Increasing efficiencies

Samsara revolutionizes our drivers' workflows by simplifying daily tasks and enhancing driver management, while providing seamless fleet tracking from our home office. With real-time, to-the-second GPS and in-depth vehicle diagnostics, we gain unparalleled visibility into our operations. This data-driven insight enables us to optimize route performance and elevate service standards. The result is faster, safer, and more reliable deliveries, ensuring that our customers receive the best possible service every time.

Safety in Action: Facility Protocol & PPE

Spill kits are placed throughout our facilities to contain spills and prevent environmental impact. They are inspected quarterly during facility checks, with usage reviewed in employee SPCC training. Our motor oil warehouse has a fire suppression system inspected annually, and we conduct regular SPCC and SWPPP inspections to monitor for spills and runoff.

Proper PPE is required for all product transfers and in designated areas. This includes steel/composite toe, slip- and oil-resistant boots, safety glasses, gloves, fall harnesses, fall arrest systems and hearing protection as needed. Fire-retardant uniforms are required when loading at terminals. Our warehouse team follows these standards daily to maintain a safe work environment.